ONE-STOP SYSTEM

At BOMUN Special Color, we operate a one-stop system covering everything from

design to final delivery, taking full responsibility for delivering the highest quality products.

Scroll Down

A One-Stop System:

From Design Planning to

Printing and Final Deliver

From Design Planning to

Printing and Final Deliver

Backed by years of know-how,

we create packaging solutions that deliver.

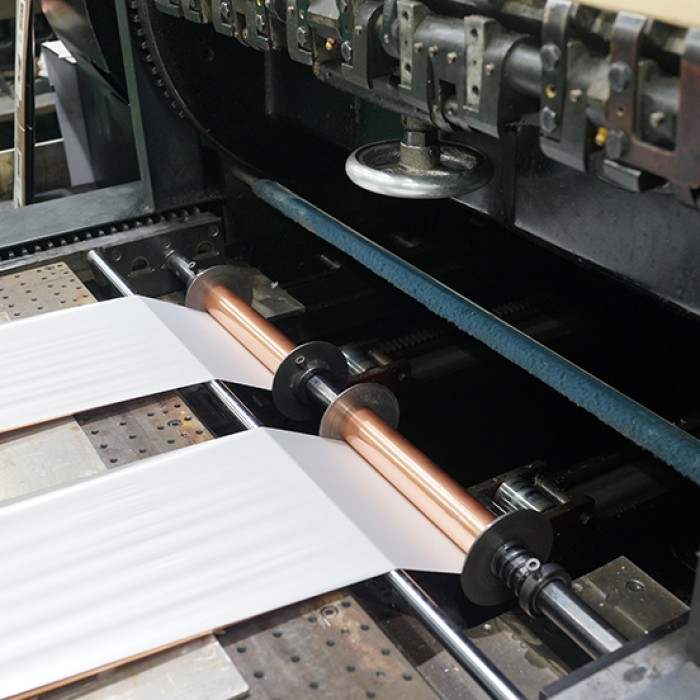

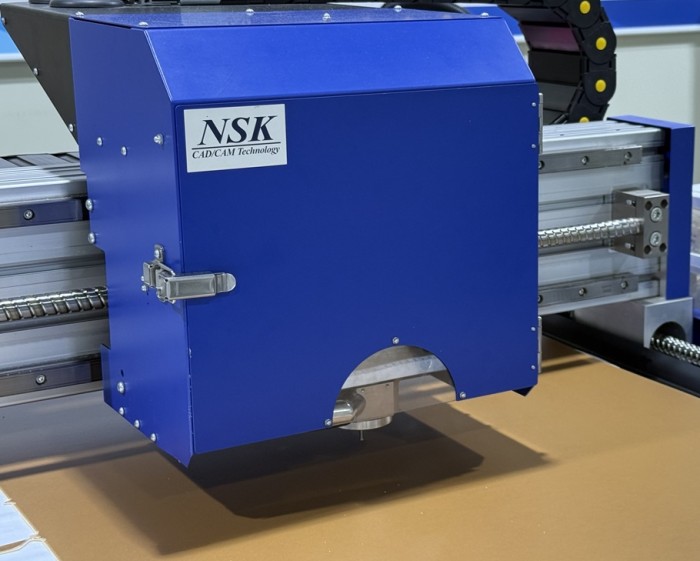

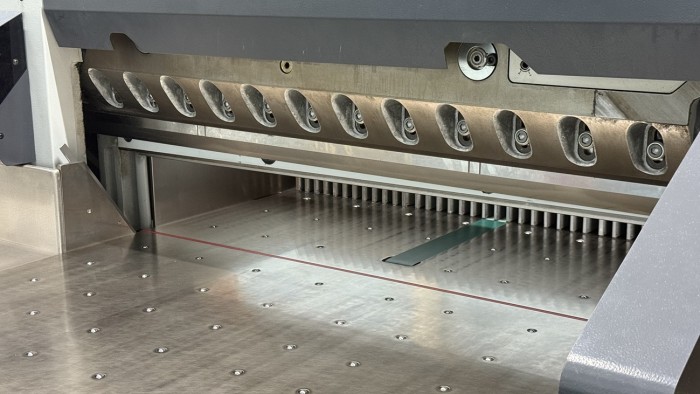

STEP. 02

Production Expertise Built on Know-How

PRODUCING

STEP. 01

Every Great Package Begins

with a Shared Vision

DESIGNING

STEP. 03

Fast and Accurate — Every Time

DELIVERY

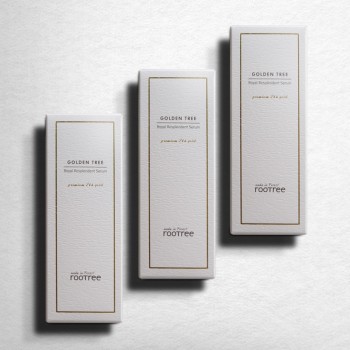

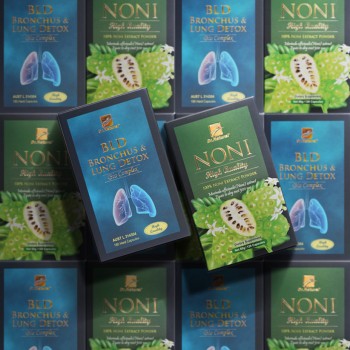

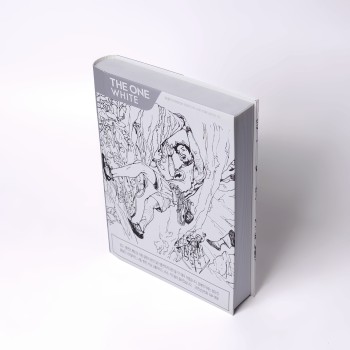

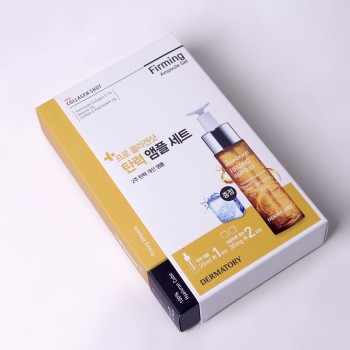

PRODUCTS

No posts available.

No posts available.

No posts available.

EQUIPMENT

At BOMUN Special Color, quality begins with a well-prepared system.

For years, we’ve focused on

one thing only “Packaging.”

With unwavering dedication,

we’ve come this far.

one thing only “Packaging.”

With unwavering dedication,

we’ve come this far.

BOMUN Special Color —

Your Partner in Shared Values

and Unmatched Excellence.

Your Partner in Shared Values

and Unmatched Excellence.

OUR CLIENTS

We collaborate with trusted partners across various industries,

delivering results you can rely on.